R&D

J-MAX conducts R&D at the forefront of the constantly evolving mobility field while continuing to look further ahead. Our pursuit of new technology development never ends.

Building on the know-how we accumulated over long years, we work continually on R&D to contribute to a reliably safe world and a more prosperous environment.

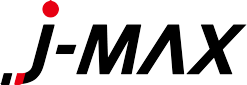

Forming analysis technology

To further evolve our CAE technology gained through long years of experience with super high tensile products, we implement trials on physical prototypes of even stronger high tensile steel and aluminum and other nonferrous metals to enhance our technological capabilities in CAE.

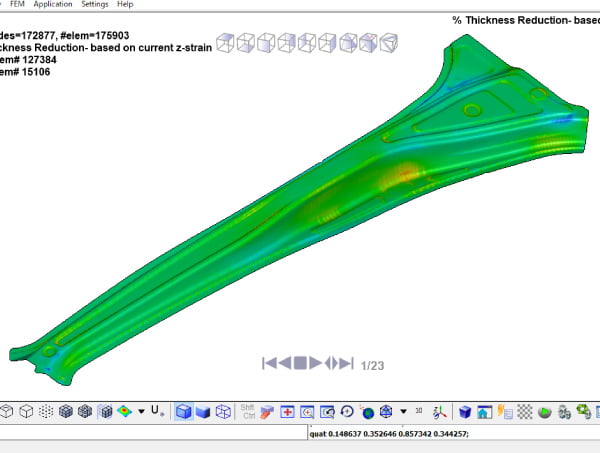

Strength and stiffness evaluation

We are developing evaluation methods such as strength, stiffness, and formation mode using CAE technology in our product development and customer proposals for product form and so on. Product evaluations are conducted virtually rather than through physical prototypes thus contributing to reducing costs and accelerating development speed.

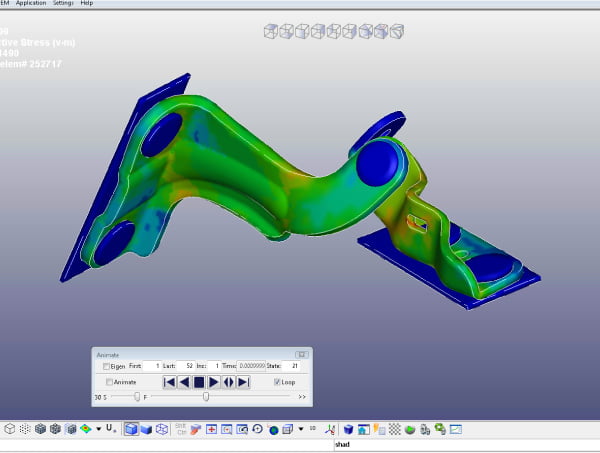

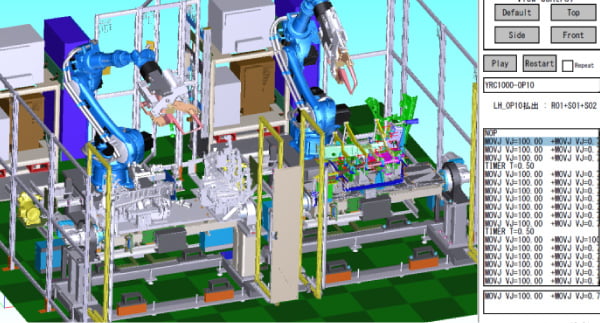

Simulation technology

We are using virtual technology aiming for process breakthroughs when ramping up new lines or conducting robot teaching and process changes. J-MAX is working to improve the accuracy of projected process improvements through migrating from desktop calculations to virtual technologies as well as moving robot learning online.

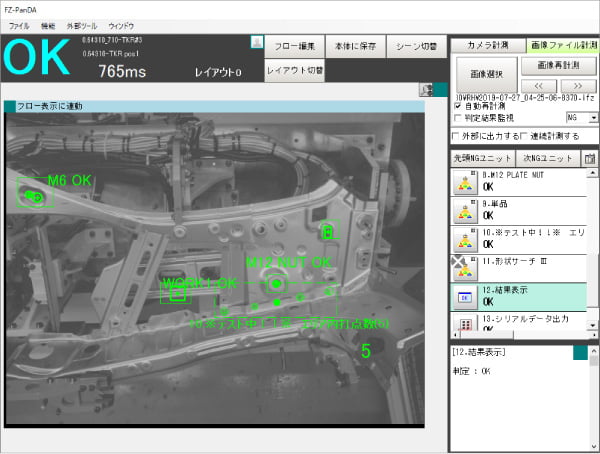

Image processing technology

Through the intensive use of image processing technology, we have replaced inspections that could only be conducted with conventional sensors. We are conducting research to apply this technology to find imperfections not detectable by sensors and to ensure accurate position correction.

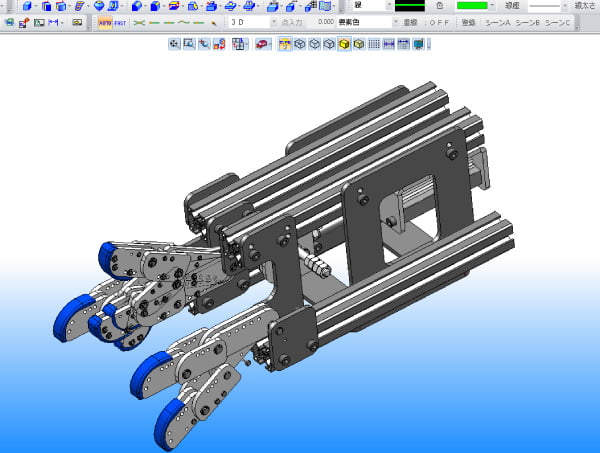

Tool development

We are developing automation tools used in manufacturing processes. We are also developing technologies and tools to replace work done to humans to robots and automation to cuts product input costs.